OT Deployment

Stellar Cyber has a flexible deployment model and a unified platform that natively supports Operational Technology (OT) security use cases. This allows immediate deployment and future proofing to new security demands. Defending both IT and OT from a single platform results in a more efficient and cost effective approach to Security Operations.

Introduction

Stellar Cyber’s integrations, Connectors and Parsers, Sensors, approach to Detections, and Partner Ecosystem address the main challenges of getting complete visibility across both IT and OT environments. Those challenges are typically:

-

Ability to integrate any IT and OT source in a single SOC Platform—Addressed by Connectors and Parsers

-

Inability to get agent-based solutions in OT environment, thus a need for agentless security solutions—Addressed by Security Sensors

-

Need for broad, out-of-the-box, detection coverage across IT, OT, and IT or OT lateral movement use cases—Addressed by approach to Detections

-

Network architecture requirements restricting unidirectional data flow or inability to deploy any sensors in an OT environment—Addressed by Partner Ecosystem

Use this guide to understand the in-depth capabilities of Stellar Cyber in OT environments, the detection use cases covered, and the deployment scenarios for network architectures and risk levels.

Technical Capabilities

Multiple Stellar Cyber components play different roles in getting coverage into OT environments and providing detection coverage. If not already familiar, it is recommended to be acquainted with Stellar Cyber’s architecture prior to continuing this guide.

The following table lists the core technologies leveraged by Stellar Cyber and the associated component in OT environments.

|

Technology |

Stellar Cyber Product Component |

Details |

|---|---|---|

| DPI |

Security & Linux Sensors |

3700 total protocols, 57 SCADA (includes iccp and dnp3), 18 IoT; entire support list detailed below. See DPI SCADA Reference. |

| IDS | Security & Linux Sensors | Real time updates from paid signature feeds. |

| Malware AV | Security Sensors | Over the wire file reconstruction and classification. |

| NTA / NDR | Data Processor | Supervised and unsupervised Machine Learning. |

| Asset Discovery | Data Processor | Asset discovery and resolution from all data sources. |

| Vulnerability Management | Security Sensor | Third party vulnerability management sensors can be installed on a Security Sensor (for example, Tenable). |

| DMZ Log Collection | Connectors, Logs via Security Sensors, Linux & Windows Sensors | Ability to collect logs from all sources within DMZ (for example, Windows jump host, Zero Trust Solution). |

| Level 3 Device Log Collection | Logs via Security Sensors, Linux & Windows Sensors | Ability to collect logs from all sources within Level 3 (for example, Engineering Workstation, Remote Access Server). |

| OT Product Log Collection | Logs via Security Sensors | Ability to collect logs from OT security products (for example, Nozomi) and OT devices (for example, Honeywell). |

| Incident Correlation | Data Processor | Analyze and investigate all alerts, across IT and OT, together automatically. |

DPI SCADA Reference

The following protocols are natively understood by Stellar Cyber’s network based Security Sensors. Stellar Cyber’s DPI understands many other protocols beyond the following SCADA reference.

|

Protocol |

Description |

|---|---|

| AAON PRISM 2 | AAON Prism 2 is a software for control of AAON HVAC, Wattmaster Commlink 5 module over IP. |

| B&R Automation | B&R Industrial Automation is a manufacturer for the industry. This plugin classifies a plastic molding machinery. |

| BACnet Application Layer | BACnet is a communication protocol for Building Automation and Control (BAC) networks defined by the standard ISO 16484-5. The BACnet stack defines different layers, the BACnet Application Layer (bacnet_app) manages access to objects exposed by BACnet devices and operations done on them. |

| BACnet Network Layer |

BACnet is a communication protocol for Building Automation and Control (BAC) networks defined by the standard ISO 16484-5. The BACnet stack defines different layers, the BACnet Network Layer (bacnet_net) contains the network addresses required for routing BACnet messages to BACnet devices. |

| BACnet Virtual Link Control | BACnet is a communication protocol for Building Automation and Control (BAC) networks defined by the standard ISO 16484-5. The BACnet stack defines different layers, the BACnet Virtual Link Control layer (bacnet_vlc) is used by BACnet devices over IP networks. It formalizes all the services that a BACnet device might require from the link layer but are not readily available from the underlying IP layer. |

| Bosch Security Conettix | Bosch Conettix is a security alarm product line. This plugin classifies the D6600 when no encryption is configured. |

| Codesys Protocol (IDE-PLC) | Codesys is an embedded system and its IDE for industrial Programmable Logic Controller (PLC). This plugin classifies the protocol between the IDE and the PLC. |

| Common Industrial Protocol | The Common Industrial Protocol (CIP) is an industrial protocol for industrial automation applications. |

| CSP AB/Ethernet | Proprietary protocol developed by Allen-Bradley, used on programmable logical controllers (PLC). |

| DeltaV | Traffic related to DeltaV, a distributed control system used in industrial process control (Emerson Process Management). |

| Distributed Network Protocol | DNP3 (Distributed Network Protocol) is a set of protocols used between components in process automation systems (SCADA). |

| DLMS/COSEM over IP | DLMS/COSEM is a standardized protocol for energy and water smart meters. This plugin classifies DLMS above the UDP or wrapper_dlms (WPDU). |

| DLMS/COSEM over IP wrapper | TCP/UDP wrapper protocol (WPDU) for transporting over IP the DLMS/COSEM (IEC-62056) protocol for energy and water smart meters. |

| Dr Schenk Inspection System | Dr Schenk Inspection System is a product that inspects and analyzes raw material from a factory production chain. It gathers sensors, actuators, and visualization components all interacting with the Inspection System. |

| EquipCommand | This layer classifies EquipCommand protocol from TotalTrax equipment (SX/VX series). It solely handles the non-ciphered part of this protocol. |

| ESK M3 | This plugin classifies the control protocol between ESK M3 Access Control module for forklifts and the P106 software that manages them. |

| Ethernet/IP | ENIP (EtherNet/IP) is an industrial network protocol that adapts the Common Industrial Protocol to standard Ethernet. |

| Experion product | This plugin classifies Experion Control Builder for Server LX. |

| fanuc gen | This layer gathers signatures of protocols used by Fanuc equipment. This layer does not cover ALL protocols generated by Fanuc equipment. |

| General Electric Proficy | Proficy is a General Electric product for industrial environments allowing monitoring and data management from the SCADA network. This plugin classifies traffic related to Proficy Gateway service (PR Gateway) and Proficy Licensing server (PR Licensing). |

| Generic Object Oriented Substation Events | GOOSE (Generic Object Oriented Substation Events) is a controlled model mechanism in which any format of data (status, value) is grouped into a data set and transmitted within a time period of 4 milliseconds. |

| High-Availability Seamless Redundancy | High-Availability Seamless Redundancy provides redundancy for industrial Ethernet networks. This header is used for packet duplication removal. The ixEngine does not run the duplication removal algorithm. |

| High-Level Data Link Control | High-Level Data Link Control (HDLC) is a data link layer protocol standardized by ISO/IEC 13239:2002. This plugin classifies Frame Type 3 when transported over TCP/IP. |

| Honeywell Process History Database | Traffic related to Honeywell Process History Database (PHD). |

| HSR/PRP supervision frame | High-Availability Seamless Redundancy (HSR) and Parallel Redundancy Protocol (PRP) provide redundancy for industrial Ethernet networks. This plugin classifies supervision frames. |

| IEC 60870-5-104 | IEC 60870-5-104 protocol (aka IEC 104) is a part of IEC Telecontrol Equipment and Systems Standard IEC 60870-5 that provides a communication profile for sending basic telecontrol messages between two systems in electrical engineering and power system automation. |

| IEC 61850 Sampled Values | IEC 61850 Sampled Measured Values (SMV or SV) is protocol used in Electrical substations to share data between Intelligent Electronic Device (IED) under hard real time constraints (IEC 61850-9-2). |

| IEEE C37.118 Synchrophasor | IEEE C37.118 Synchrophasor Protocol conveys electrical current measurements in power grid substations. |

| Inter-Control Center Communications Protocol | IEC 60870-6/TASE.2. Inter-Control Center Communications Protocol (ICCP) provides data exchange over Wide Area Networks (WANs) between utility control centers, utilities, power pools, regional control centers, and Non-Utility Generators. |

| Intermec SmartSystem Foundation | Intermec (Honeywell subsidiary) SmartSystem is a barcode scanner fleet management software. |

| Invar Systems AS/RS Control | Invar Systems AS/RS (Automated Storage and Retrieval System) control protocol is part of Invar's integrated warehouse software system (IWS). |

| iWarehouse | iWarehouse is the fleet and warehouse management system of Raymond Corporation (a subsidiary of Toyota Industries that manufactures and distributes electric lift trucks). This plugin classifies the protocol of the on-board device, named Monitor. |

| KEYENCE Barcode Reader | This plugin classifies the control protocol of KEYENCE Barcode Reader products, also used by their setup software (AutoID Network Navigator). |

| Lenel OnGuard client | OnGuard is a product from Lenel for managing physical security of buildings. This plugin classifies the connection from the client software to the server. |

| Manufacturing Message Specification (ISO 9506) | ISO 9506 Manufacturing Message Specification (MMS). |

| Mercury Security | This plugin classifies Mercury Security controllers communication protocol with TLS disabled. Mercury security controllers manage physical access control (doors and card readers) to buildings. |

| Mettler Toledo Standard Interface Command Set | Standard Interface Command Set (SICS) is a protocol to control Mettler Toledo industrial scales. |

| Modbus | Modbus is a standard communication protocol in industry for connecting industrial electronic devices (SCADA). Here, we consider modbus as the combination of Modbus/TCP (Transport layer for TCP/IP networks) and Modbus (serial communication protocol). |

| Modbus Remote Terminal Unit | Traffic related to Modbus Remote Terminal Unit (RTU), a distributed control system used in industrial process control. The Modbus RTU communications can be sent to the network using a basic RS485 to TCP adapter. |

| Moxa Async Server Proprietary Protocol (ASPP) | This plugin classifies ASPP (Async Server Proprietary Protocol) from Moxa (NPort devices) without activation of encryption. |

| Omron FINS protocol | Omron FINS Protocol is SCADA protocol to communicate with PLC. |

| OPC Unified Architecture | OPC is the interoperability standard for the secure and reliable exchange of data in the industrial automation space and in other industries. This plug-in classifies the OPC Unified Architecture (UA) binary protocol over TCP. |

| Parallel Redundancy Protocol | Parallel Redundancy Protocol provides redundancy for industrial Ethernet networks. This plugin detects the Redundancy Control Trailer (RCT) to Ethernet frames. The ixEngine does not run the duplication removal algorithm. |

| PC-cubed | PCCC is Programmable Controller Communication Commands, which is used to control software running in Programmable Logic Controller (PLC). PCCC traffic can be hardware-specific. This plugin addresses traffic generated by Rockwell/Allen-Bradley to talk to SLC5, PLC5E, and MicroLogix PLC for service. |

| PI AF | OSI PI Analysis Framework SCADA protocol (AF Server, MDB Sync, etc.). |

| PI Data Archive | OSI PI DataArchive and Server SCADA protocol (ProcessBook, Datalink, etc.). |

| Process Field Net | PROFINET (an acronym for Process Field Net) is an industry technical standard for data communication over Industrial Ethernet, designed for controlling and collecting data from equipment in industrial systems, with a particular strength in delivering data under tight time constraints (1ms or less). The standard is maintained and supported by Profibus & Profinet International, an umbrella organization headquartered in Karlsruhe, Germany. |

| Rockwell RNA protocol | Rockwell Network Applications (RNA) is a Rockwell implementation of Windows DNA-M and is used for communication between Rockwell FactoryTalk products. |

| s7 Communication | S7comm (S7 Communication) is a Siemens proprietary protocol that runs between programmable logic controllers (PLCs) of the Siemens S7-300/400 family. It is used for PLC programming, exchanging data between PLCs, accessing PLC data from SCADA (supervisory control and data acquisition) systems, and diagnostic purposes. |

| S7 Communication Plus | S7communication Plus is a Siemens proprietary protocol for Siemens' Programmable Logic Controllers (PLC). |

| Schneider Integrated Object Network | Integrated Object Network (ION) is a proprietary SCADA protocol for Schneider Electrics smart meters. |

| SeamLess Message Protocol | SeamLess Message Protocol (SLMP) is for the control of Mitsubishi PLC devices. |

| Siemens Apogee | This plugin classifies the main data protocol used by Siemens Apogee HVAC product line. This device also uses BACnet and other control protocols that are not covered here. |

| Socomec | Socomec is a manufacturer for industrial power networks. This plugin classifies the monitoring socket of the Silverlight user interface for the PassIP+ gateway to the proprietary ISOM bus. It is used for insulation fault detection. |

| Toyo PLC protocol | This layer classifies only a limited number of protocols known to be used by Toyo hardware (PLC). |

| Vnet/IP | Yokogawa's control communication network approved by international standards (IEC 61784-2 Ed.2.0). |

| Yokogowa protocol | This layer classifies only a limited number of protocols known to be used by Yokogowa hardware. |

IDS Signature Reference

Stellar Cyber’s Security Sensors are continuously updated with signatures from Proofpoint ET Pro out-of-the-box. The ruleset contains coverage against OT attacks, for example, SCADA and IoT. With an upcoming release of Stellar Cyber’s Threat Intelligence feature, all signatures will become searchable in the platform itself.

Detection Use Cases

From the technologies described above, visibility and detections are created that can be used to cover key use cases related to defending OT.

|

Use Case |

Methodology |

|---|---|

| Non-Standard SCADA Protocol Detection |

|

| SCADA Network Segmentation Violation |

|

| Network Attack Detection |

|

| Malicious or Suspicious File |

|

| Anomalous Communication / Process / Port / Data Transfer |

|

| IT to OT Lateral Movement |

|

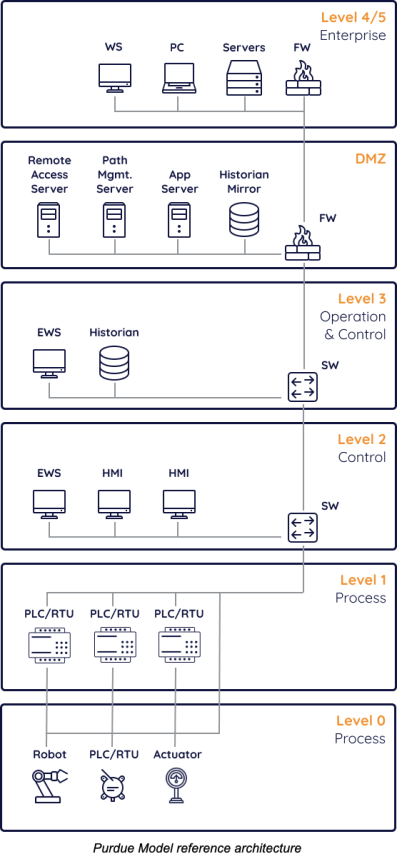

Deployment Scenarios

Getting visibility into OT environments depends on a number of factors of how those networks are managed to include connectivity and managed infrastructure. The following deployment scenarios will reference the Purdue Model, which is a network and device segmentation guideline for Industrial Control Systems (ICS). For an overview of the Purdue Model, reference this overview from ZScaler.

Stellar Cyber can be flexibly deployed depending on the OT network architecture and risk levels. Use the following table for understanding which deployment scenario is best suited for your enterprise. For the most comprehensive solution, Stellar Cyber recommends deployment scenario (1). For the easiest to deploy, easiest to maintain, and lowest risk solution, Stellar Cyber recommends deployment scenario (2).

|

Deployment Scenario |

Description |

Technologies Required |

|---|---|---|

| (1) Sensors Deployed to Level 3 & 2 Switches |

Security Sensors are deployed, as hardware or VMs, in Level 3 and 2, and mirror relevant switch traffic. When you would do this

|

|

| (2) Sensors Deployed in Level 4 With Traffic Visibility |

Security Sensors are deployed, as hardware or VMs, in Level 4 and receive mirrored traffic from Level 3 switches and below. When you would do this

|

|

| (3) Sensors Deployed in Level 4 With No Traffic Visibility |

Security Sensors are deployed, as hardware or VMs, in Level 4 and receive any available syslog sources from Level 3 and below. When you would do this

|

|

| (4) Airgap | If an OT environment is truly air gapped, there is no network path to receive any telemetry back to Stellar Cyber. Stellar Cyber can be deployed in an air gapped network, however it would be unproductive to have a single instance of Stellar Cyber for a single air gapped IT environment. | N/A |

| (5) Combination of Scenarios | If certain OT environments have different risk levels or networking infrastructure, some combination of scenarios (1), (2), and (3) can be deployed. |

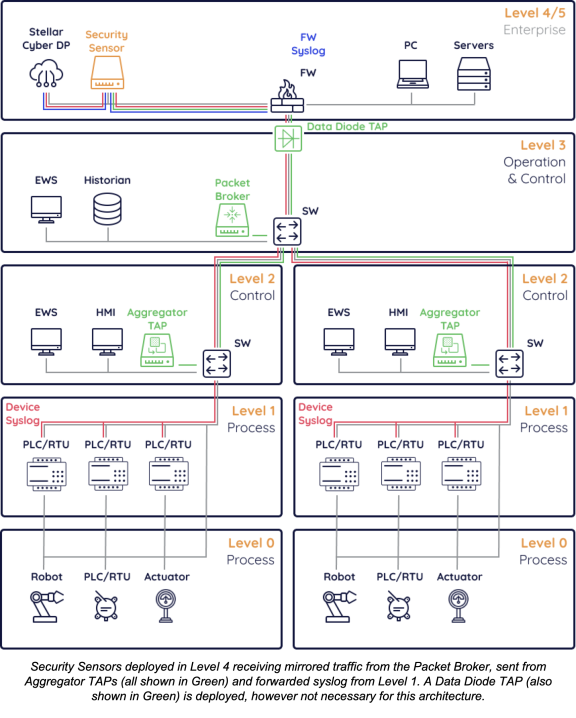

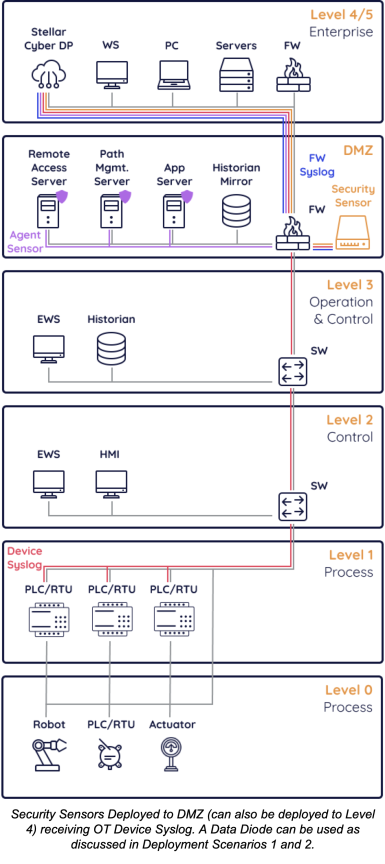

In the subsequent scenario subsections, diagrams detail specific capabilities deployed in certain locations, along with what telemetry is collected from where (both color coded for reference).

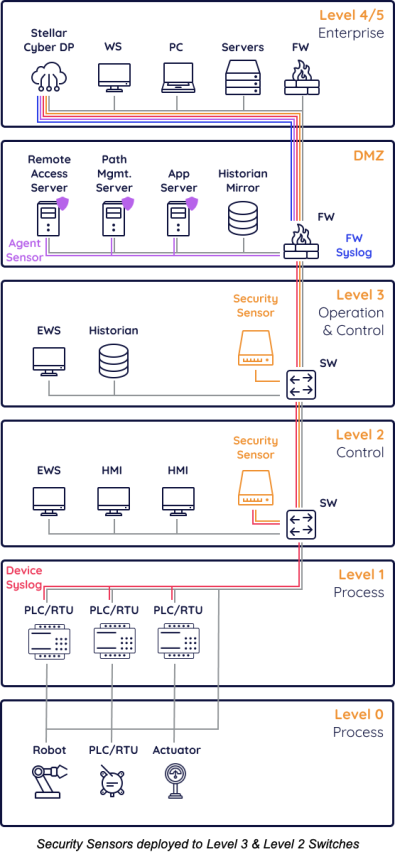

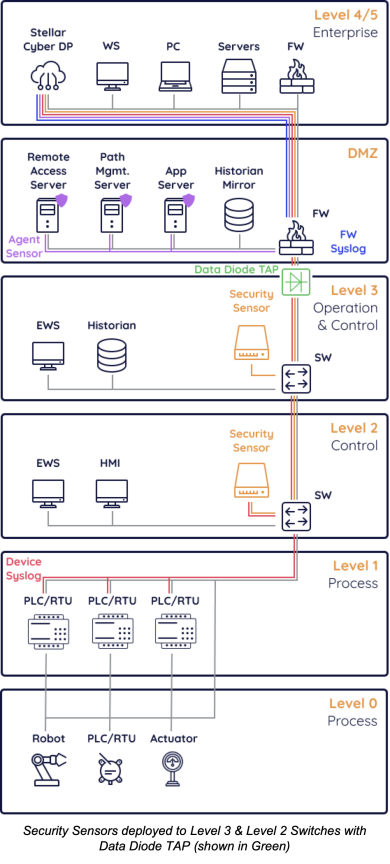

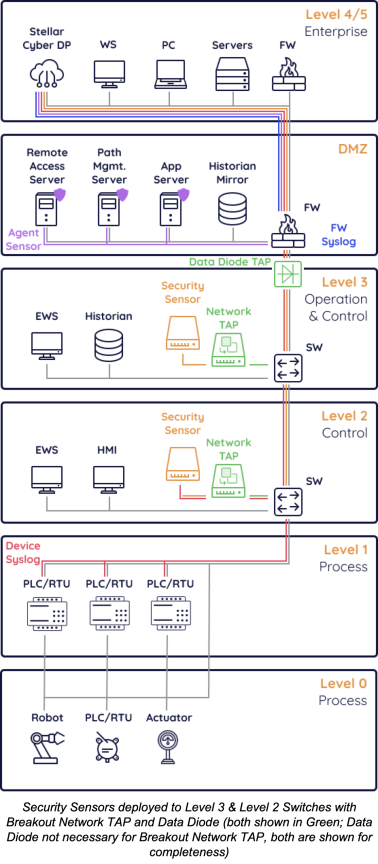

(1) Sensors Deployed to Level 3 & 2 Switches

Pros: This scenario is the maximal security coverage because it allows for capabilities like Vulnerability Management to be deployed and device level syslog to be easily collected.

Cons: It involves installing agentless software or new hardware in Level 3 or below, which comes with risk and bureaucratic process.

The following diagram shows several integrations and components deployed. Not everything here is strictly necessary (such as, DMZ server logs, Firewall Syslog, OT Device Syslog), however recommended for maximal coverage.

Components and integrations deployed:

-

Device Syslog (Red)—Any OT device capable of forwarding syslog events sends events to a Security Sensor to then forward to the Data Processor

-

Security Sensors (Orange)—Security Sensors are deployed off of core OT switches, mirroring traffic to perform capabilities including Network Traffic Analysis (NTA), Deep Packet Inspection (DPI), Intrusion Detection System (IDS), Malware Sandbox, and Vulnerability Management (VM)

-

Server Sensors (Purple)—Small agents used for log collection can be deployed on DMZ servers

-

Firewall Syslog (Blue)—DMZ and above Firewalls can forward syslog to the Data Processor or Security Sensors

-

Data Processor (Grey)—The Data Processor can be deployed on-premise or as a SaaS solution

Data Diode TAP Usage

Why Use A Data Diode TAP—A Data Diode TAP is used in circumstances when it is required to restrict data to only be able to flow from Level 3 to Level 4, and not vice versa. This is often recommended and provides significant security benefits. However, there is still a need to monitor Level 3 and below because there are attacks that can bypass such network segmentation.

Deployment Implications—Without direct access to the Data Process, Security Sensors will have to be manually updated.

Data Flow Implications—For telemetry collection, none, because data can still be sent out of the OT network. However, Security Sensors will not get up-to-date signatures because they will not have Internet Access.

A Data Diode can also be deployed along with a Breakout Network TAP discussed below.

Breakout Network TAP Usage

Why Use A Breakout Network TAP—A Breakout Network TAP allows traffic mirroring from legacy switches that do not natively support this functionality or unmanaged switches that cannot be configured.

Deployment Implications—Everything else should be deployed the same, however you will want to ensure the Security Sensor is getting both traffic mirroring from the Breakout Network TAP and can still receive syslog from any OT devices.

Data Flow Implications—None.

(2) Sensors Deployed in Level 4 With Traffic Visibility

Pros: This scenario is the easiest to deploy and less risky from a perspective of introducing new products within the OT environment, while maintaining much of the visibility from deployment scenario (1). Security Sensors can auto update since they have access to download software from the Data Processor.

Cons: It does involve acquiring additional networking technologies, specifically Aggregator Network TAPs and a Packet Broker. Some log collection may be more challenging if syslog cannot be easily streamed out of the environment, and certain capabilities like Vulnerability Management will not be deployable to Level 3 and below.

The following diagram shows several integrations and components deployed. Not everything here is strictly necessary, however recommended for maximal coverage.

Components and integrations deployed:

-

Device Syslog (Red)—Any OT device capable of forwarding syslog events sends events through the Data Diode TAP to a Security Sensor to then forward to the Data Processor

-

Security Sensor (Orange)—A Security Sensor is deployed in Level 4 receiving mirrored traffic from the Packet Broker in Level 3, which allows it to perform capabilities including Network Traffic Analysis (NTA), Deep Packet Inspection (DPI), Intrusion Detection System (IDS), and Malware Sandbox

-

Firewall Syslog (Blue)—Level 4 Firewalls can forward syslog to the Data Processor or Security Sensors

-

Data Processor (Grey)—The Data Processor can be deployed on-premise or as a SaaS solution

-

Aggregator TAP (Green)—Mirrors network traffic from one or many switches with the purpose of forwarding to a Packet Broker

-

Packet Broker (Green)—Receives and forwards traffic from one or many Aggregator TAPs or Network Breakout TAPs to then forward as a single stream to a Security Sensor

-

Data Diode TAP (Green)—Physically enforces unidirectional communication between Level 4 and Level 3

Data Diode TAP Usage

Why Use A Data Diode TAP—A Data Diode TAP is used in circumstances when it is required to restrict data to only be able to flow from Level 3 to Level 4, and not vice versa. This is often recommended and provides significant security benefits. However, there is still a need to monitor Level 3 and below because there are attacks that can bypass such network segmentation. In this deployment scenario, there would likely be a Data Diode TAP required, given the decision to not place Security Sensors in Level 3 and below, although it is not technically necessary.

Deployment Implications—This deployment scenario already places Security Sensors at Level 4, so there are no implications other than setting up the Data Diode TAP.

Data Flow Implications—This deployment scenario already places Security Sensors at Level 4, so there are no implications.

(3) Sensors Deployed in Level 4 With No Traffic Visibility

Pros: This scenario does not place any new products in the OT environment. Security Sensors can auto update since they have access to download software from the Data Processor.

Cons: Losing traffic level visibility in the OT environment significantly limits detection use cases.

The following diagram shows several integrations and components deployed. Not everything here is strictly necessary (such as, DMZ server logs, Firewall Syslog, OT Device Syslog), however recommended for maximal coverage.

Components and integrations deployed:

-

Device Syslog (Red)—Any OT device capable of forwarding syslog events sends to a Security Sensor to then forward to the Data Processor

-

Security Sensor (Orange)—A Security Sensor is deployed in the DMZ and is only acting as a Log Forwarder since it has no access to OT network traffic

-

Server Sensors (Purple)—Small agents used for log collection can be deployed on DMZ servers

-

Firewall Syslog (Blue)—All DMZ and above Firewalls can forward syslog to the Data Processor or Security Sensors

-

Data Processor (Grey)—The Data Processor can be deployed on-premise or as a SaaS solution

(4) Airgap

Pros: Strict network segmentation between OT and IT environments.

Cons: Not any security gains in practice compared to a Data Diode preventing data transmission one way at the physical layer. Additionally, a true airgap is operationally painful, and inherently obscures security visibility.

(5) Combination of Scenarios

The deployment scenarios above can easily be combined for enterprises that have multiple OT environments that need various approaches to security. For example, a water treatment enterprise may have many small sites and a single large water processing site. For the small sites, each one implements Deployment Scenario (2). However for the large site, Deployment Scenario (1) is implemented. All data ends up at a single Data Processor to defend all OT environments in addition to any IT environments.

Technology Options For OT Networking

Stellar Cyber is, from a technical perspective, agnostic to different networking solution providers for Data Diodes, Network Breakout TAPs, Aggregator TAPs, and Packet Brokers. However, Garland Technology is Stellar Cyber’s preferred and recommended vendor to work with as they have an extensive portfolio of products completely focused on the different networking and visibility challenges faced by OT environments.